Aluminium Pattern Sheets

The high strength-to-weight ratio and raised anti-skid patterns make ALuminium Pattern sheets ideal...

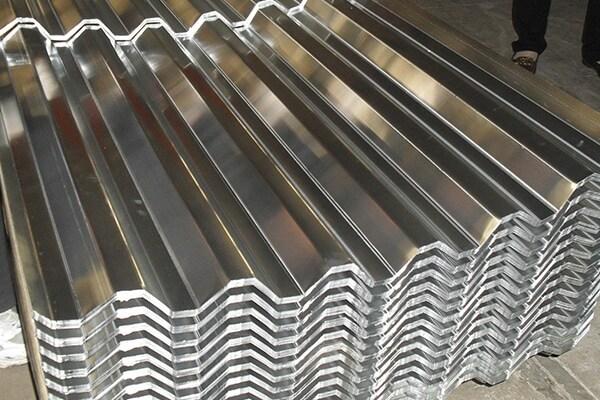

Aluminum coils can be produced from aluminum ingots or other forms of raw aluminum (called cold rolling or direct casting) or from a smelting process directly through rolling (called continuous casting). These sheets of rolled aluminum are then rolled up, or coiled, around a core. Our aluminum coils are precision-finished to match international standards. They have good shape, high tolerance, versatility, and blemish-free surfaces. They are used in commercial and general engineering applications such as bus bodies, cladding, and fan blades. The company meets the demands of its ever-growing clientele with continuous upgrades and process improvements.

Leading Aluminium Coil Supplier in India

Looking for a legit Aluminium Coil Supplier in India? Santhana Lakshmi Metals is your trusted source, leading the pack among Aluminium Coil Manufacturers in India. We bring the heat with top-tier aluminium coils that are durable, corrosion-resistant, and packed with superior conductivity. Whether you need alloyed, pure, or tempered coils, we've got you covered with a range that’s perfect for industries like automotive, construction, electrical, and packaging. We're all about delivering custom solutions that fit your vibe, backed by reliable service and prices that won’t break the bank. When it comes to aluminium coils in India, Santhana Lakshmi Metals is the real deal.

Leading the Charge in Sustainable Aluminium Production

Beyond the metal, we're all about shaping a future where sustainability and top-notch quality lead the way. As a leading Aluminium Coil Supplier in India, Santhana Lakshmi Metals is flipping the script on eco-friendly practices in aluminium coil production. We’re committed to cutting-edge methods that reduce energy consumption and minimize waste. Our process is powered by green energy sources like solar and wind, and we focus on recycling aluminium to maintain a circular approach. With our zero-waste mindset and transparent practices, we're not just producing premium coils—we're making a real impact on the planet. Choose us and join the movement towards a greener, smarter future.

Why Our Aluminium Coils Stand Out?

Check out why Santhana Lakshmi Metals, a top-tier Aluminium Coil Manufacturer in India, is your ultimate pick for industries nationwide. Our coils are crafted for next-level durability and peak performance, thanks to cutting-edge production tech and top-notch quality control. Whether you're tackling heavy-duty projects or fine-tuning intricate components, our products deliver game-changing reliability and efficiency. We offer customization options to ensure our coils fit your project like a glove. Experience the difference with our high-quality aluminium coils, engineered to surpass industry standards and help you crush your goals with style.

|

Technique |

ROLLING |

|

|

STANDARD |

ASTM-B-209M , EN573 AND THE ALUMINIUM ASSOCIATION |

|

|

Dimensions |

Parameter |

|

|

Thickness (mm) |

||

|

Width (mm) |

||

|

Length (mm) MAX |

||

|

COIL OD |

||

|

CORE ID |

||

|

BUNDLE WEIGHT |

||

|

PACKAGE |

The coils are packed in eye-to-sky or eye-to-wall position, wrapped in HDPE and hardboard, strapped with hoop iron and placed on wooden pallets. Moisture protection is provided by silica gel packets. |

|

|

APPLICATION |

Bus cabins and bodies | Insulation | Cladding in buildings | aluminium composite panels |false ceiling | panelling (plain or colour-coated coils) | Electrical busbar ducting, flexibles, transformer strips, etc |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Alloy Equivalents |

||||||||||

|

Alloy (%) |

INDIA (IS) |

UK (BS) |

USA (AA) |

CANADA (AICAN) |

GERMANY (DIN) |

ASTM |

JAPAN (JIS) |

FRANCE (AFNOR) |

RUSSIA |

|

|

AA 1050 |

19500 |

E1B |

1050 OR 1060 |

IS |

Al 99.5 |

99.6 A |

Al-1 |

A-5 |

- |

|

|

AA 1100 |

19000 |

E1C |

1100 |

2S |

AL 99.0 |

99.0 A |

AL-3 |

A-4 |

A-2 |

|

|

AA 1200 |

|

|

|

|

|

|

|

|

|

|

|

AA 3003 |

|

|

|

|

|

|

|

|

|

|

|

AA 3004 |

|

|

|

|

|

|

|

|

|

|

|

AA 3103 |

- |

NE-3 |

3103 |

3S |

Al Mn |

- |

- |

3103 |

- |

|

|

AA 3105 |

|

|

|

|

|

|

|

|

|

|

|

AA 5005 |

|

|

|

|

|

|

|

|

|

|

|

AA 5052 |

52000 |

NE-4 |

5052 |

M57S |

AlMg2 |

GR 20A |

A2-Si |

A-G3 |

AM |

|

|

AA 5251 |

|

|

|

|

|

|

|

|

|

|

|

AA 8011 |

|

|

|

|

|

|

|

|

|

|

|

Mechanical Properties |

|||||||

|

Alloy (AA) |

Temper |

UTS (mpa) |

%E (min) |

||||

|

Min |

Max |

(50mm gauge length) |

|||||

|

0.50 — 0.80 mm |

0.80 — 1.30 mm |

1.30 — 2.60mm |

2.60 — 4.00 mm |

||||

|

1050 |

O |

55 |

95 |

22 |

25 |

29 |

30 |

|

1050 |

H14 |

95 |

125 |

4 |

5 |

6 |

6 |

|

1050 |

H18 |

125 |

- |

3 |

3 |

4 |

4 |

|

1070 |

O |

- |

95 |

27 |

27 |

29 |

34 |

|

1070 |

H14 |

95 |

120 |

4 |

5 |

6 |

7 |

|

1070 |

H18 |

120 |

- |

3 |

3 |

4 |

4 |

|

1200, 1100 |

O |

70 |

110 |

20 |

25 |

29 |

30 |

|

1200, 1100 |

H14 |

105 |

140 |

3 |

4 |

5 |

5 |

|

1200, 1100 |

H16 |

125 |

150 |

2 |

3 |

4 |

4 |

|

1200, 1100 |

H18 |

140 |

- |

2 |

2 |

3 |

3 |

|

3103, 3003 |

O |

90 |

130 |

20 |

23 |

24 |

24 |

|

3103, 3003 |

H14 |

130 |

180 |

3 |

4 |

5 |

5 |

|

3103, 3003 |

H16 |

150 |

195 |

2 |

3 |

4 |

4 |

|

3103, 3003 |

H18 |

170 |

- |

2 |

2 |

3 |

3 |

|

3004 |

O |

150 |

200 |

10 |

|||

|

3004 |

H32 |

193 |

240 |

1 |

|||

|

3004 |

H34 |

220 |

260 |

1 |

|||

|

3004 |

H36 |

240 |

280 |

1 |

|||

|

3004 |

H38 |

260 |

- |

1 |

|||

|

3105 |

O |

95 |

145 |

14 |

14 |

15 |

16 |

|

3105 |

H14 |

150 |

200 |

4 |

4 |

5 |

5 |

|

3105 |

H16 |

175 |

215 |

2 |

2 |

3 |

4 |

|

3105 |

H18 |

195 |

- |

1 |

1 |

1 |

2 |

|

5005 |

O |

103 |

144 |

12 |

|||

|

5005 |

H32 |

117 |

158 |

3 |

|||

|

5005 |

H34 |

137 |

180 |

2 |

|||

|

5005 |

H36 |

158 |

200 |

1 |

|||

|

5005 |

H38 |

180 |

- |

1 |

|||

|

5052 |

O |

170 |

210 |

14 |

|||

|

5052 |

H32 |

210 |

260 |

4 |

|||

|

5052 |

H34 |

230 |

280 |

3 |

|||

|

5052 |

H36 |

255 |

300 |

2 |

|||

|

5052 |

H38 |

268 |

- |

2 |

|||

|

5251 |

O |

160 |

200 |

13 |

|||

|

5251 |

H32 |

190 |

230 |

3 |

|||

|

5251 |

H34 |

210 |

250 |

3 |

|||

|

5251 |

H36 |

230 |

270 |

3 |

|||

|

5251 |

H38 |

255 |

- |

2 |

|||

|

8011 |

O |

85 |

120 |

20 |

23 |

25 |

30 |

|

8011 |

H14 |

125 |

160 |

3 |

4 |

5 |

5 |

|

8011 |

H16 |

150 |

180 |

2 |

3 |

4 |

4 |

|

8011 |

H18 |

175 |

- |

2 |

2 |

3 |

3 |

The high strength-to-weight ratio and raised anti-skid patterns make ALuminium Pattern sheets ideal...

Aluminum Foil is one of our core products, Supplied with meticulous attention to detail. We prioriti...

3105 is one of the most widely used anti rust aluminium, with slightly higher strength than that of...

Aluminum sheets are precision-finished to meet international standards for tight thickness, toleranc...